砂石同出

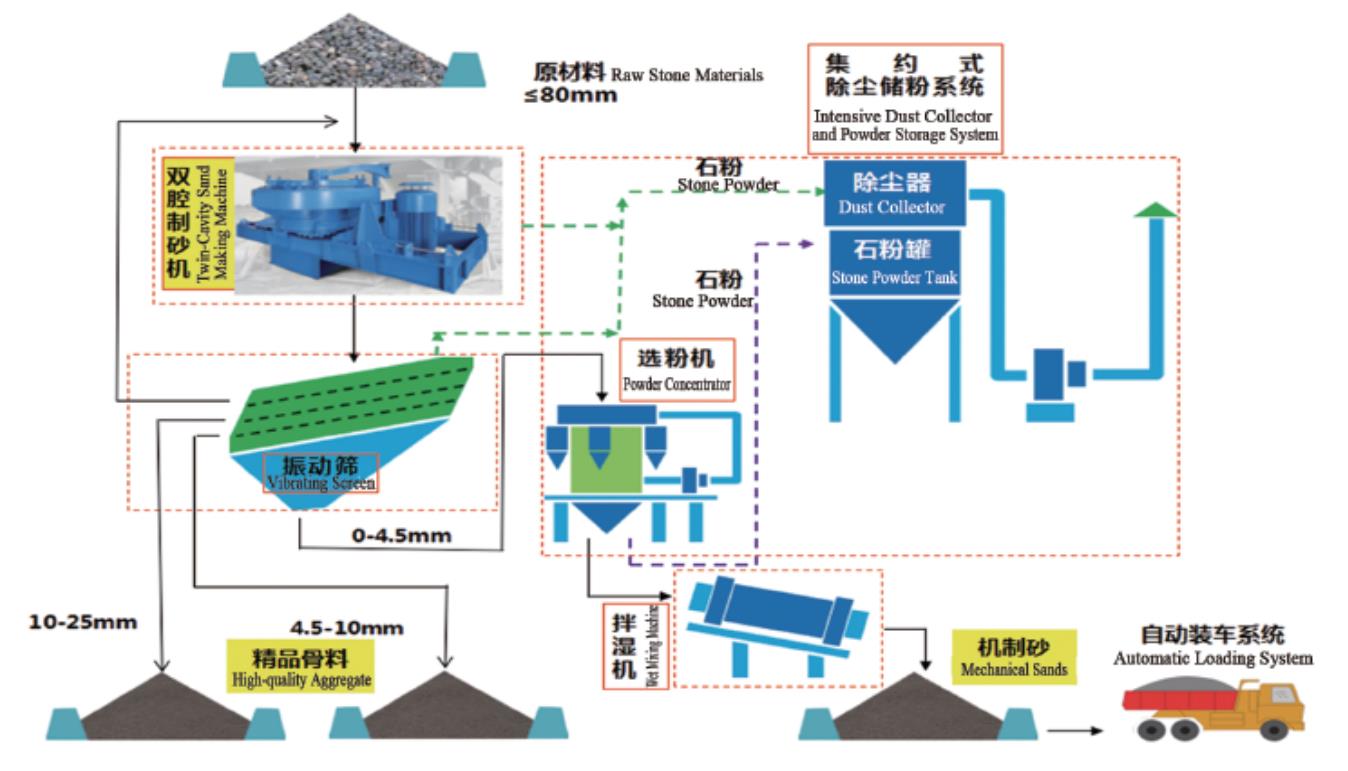

砂、石同出300tph制砂系統(tǒng) —— 混凝土攪拌站/300TPH SAND AND AGGREGATE MAKING SYSTEM—CONCRETE MIXING PLANT

- 本系統(tǒng)機(jī)制砂顆粒級(jí)配和級(jí)配類(lèi)別符合建設(shè)用砂GB/T14684-2011建設(shè)用砂guojia標(biāo)準(zhǔn)。

- 砂的石粉含量≤10.0,含泥量≤3.0%,泥塊含量≤1.0%。

- 當(dāng)機(jī)制砂MB值≤1.4或快速法試驗(yàn)合格,石粉含量≤10.0%,泥塊含量≤1.0;

- 當(dāng)機(jī)制砂MB值>1.4或快速法試驗(yàn)合格,石粉含量≤3.0%,泥塊含量≤1.0%。

- 采用硫酸鈉溶液法進(jìn)行試驗(yàn),砂的質(zhì)量損失≤8.0%;單級(jí)zui大壓碎指標(biāo)≤25%;

- 砂的表觀密度不小于2500kg/m³,松散堆積密度不小于1400kg/m³,空隙率不大于44%。

-

- The mechanical sand size grading and grading categories of the system conforms to National Standard GB/T14684-2011 Sand for Construction.

- Stone powder content of sands ≤10.0; silt content≤3.0%; clay lump content ≤1.0%.

- When MB value of mechanical sand ≤1.4 or the fast test is qualified, the stone powder ≤10.0% and the clay lump content ≤1.0%.

- When MB value of mechanical sand >1.4 or the fast test is qualified, the stone powder ≤3.0% and the clay lump content ≤1.0%.

- When the sulfate solution method is adopted to conduct a test, quality loss of sands ≤8.0%; the max. single stage crushing index ≤25%;

- Apparent density of sands not <2500kg/m3; loose bulk density not <1400kg/m3; porosity not >44%.

設(shè)備選型叁數(shù)表/PARAMETER LIST

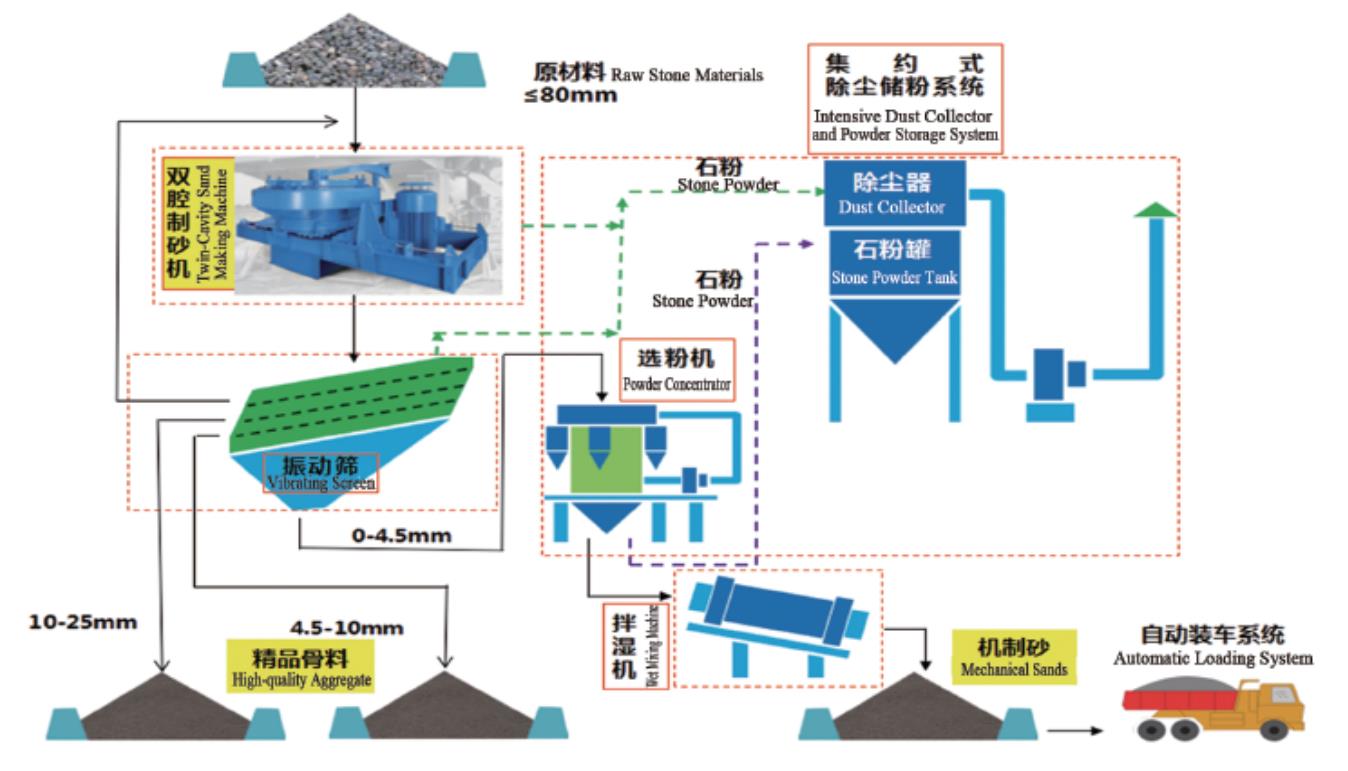

研發(fā)理念/R&D CONCEPT

系統(tǒng)優(yōu)勢(shì)/ADVANTAGES

原材料的要求/REQUIREMENTS ON RAW STONE MATERIALS